Coaxial Tube Heat Exchangers for HVAC/R Systems

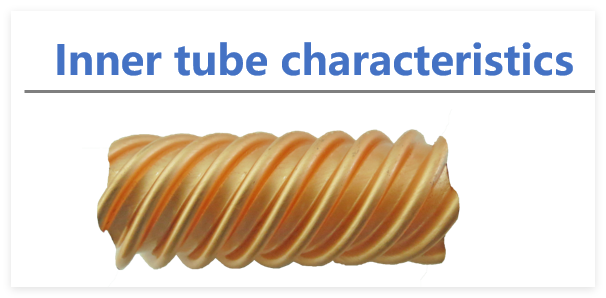

Our coaxial tube heat exchangers feature a spiral-wound copper or stainless-steel inner tube housed in a robust outer shell. This design ensures high heat transfer efficiency, reduced fouling risk, and excellent corrosion resistance.

They are widely applied in air conditioning units, water chillers, and heat pump systems where stable performance and space-saving installation are required. The advanced design enables smooth refrigerant flow, low noise, and reduced energy consumption, making them an excellent choice for both residential and commercial HVAC/R applications.

Key Features

- Compact design for easy installation and low footprint

- High heat transfer efficiency with low refrigerant charge

- Low pressure drop for stable system operation

- Multiple coil profiles available: trombone, rectangular, helix (round), spiral, and double-wound helix

- Enhanced inner tube surface (spiral/mesh-tooth structure) for improved heat transfer efficiency

- Anti-fouling / self-cleaning effect, not easily clogged in water or brine applications

- Multi-circuit configurations available (3/4/6/8 inner tube heads) to meet different capacity requirements

- Copper, stainless steel, or coated steel options available

- Anti-fouling and anti-corrosion construction for long service life

- Quiet operation with energy-saving performance

- Optional insulation, brackets, and coating available for specific installation needs

- Customized dimensions and capacities available

Applications

- Residential & commercial air conditioners

- Heat pump water heaters

- Chillers and refrigeration units

- Industrial cooling and heating systems

- Renewable energy systems (geothermal & solar heat pumps)

Specifications (Typical Range)

- Heat transfer capacity: 1 kW – 200 kW (customizable)

- Applicable refrigerants: R22, R134a, R407C, R410A, R32, R290, R404A, R454C, etc.

- Max working pressure: up to 4.5 MPa (depending on model/design)

- Materials: Copper / Stainless steel 304/316 / Epoxy-coated steel (other materials available upon request)

- Connection type: Copper pipe ends / threaded / welded connections

- Orientation: Horizontal or vertical installation

- Customization: Dimensions and coil sizes available

| Model | Inner Tube Material | Outer Tube Material | Heat Exchange Capacity (kW) | Length (mm) | OD (mm) | Notes |

|---|---|---|---|---|---|---|

| KAK-K-1.5 | Copper | Copper | 1.5 | 300 | Φ90 | Compact unit, small chillers |

| KAK-K-3 | Copper | Copper | 3.0 | 450 | Φ100 | Standard A/C units |

| KAK-K-5 | Copper | Copper | 5.0 | 600 | Φ120 | Widely used in heat pumps |

| KAK-K-8 | Copper | Copper | 8.0 | 750 | Φ133 | Medium chillers |

| KAK-K-12 | Copper | Copper | 12.0 | 1000 | Φ159 | Large A/C or water chillers |

| KAK-KS-5 | Stainless Steel | Copper | 5.0 | 600 | Φ120 | For corrosive environments |

| KAK-KS-12 | Stainless Steel | Stainless Steel | 12.0 | 1000 | Φ159 | Industrial-grade |

FAQ:

A1: R22, R134a, R407C, R410A, R32, R290, R404A, R454C, and more.

A2: Yes, tube material, coil size, capacity range, and connection type can all be customized.

A3: With proper installation and maintenance, over 10–15 years depending on operating conditions.

A4: Yes, stainless steel 316 versions are available for high-corrosion environments.

A5: We can provide the following compliance documentation upon request:

PED (2014/68/EU) compliance / CE support documents

RoHS compliance declaration

REACH SVHC compliance statement

UL compliance (if required, please confirm the applicable UL standard)

Related Products