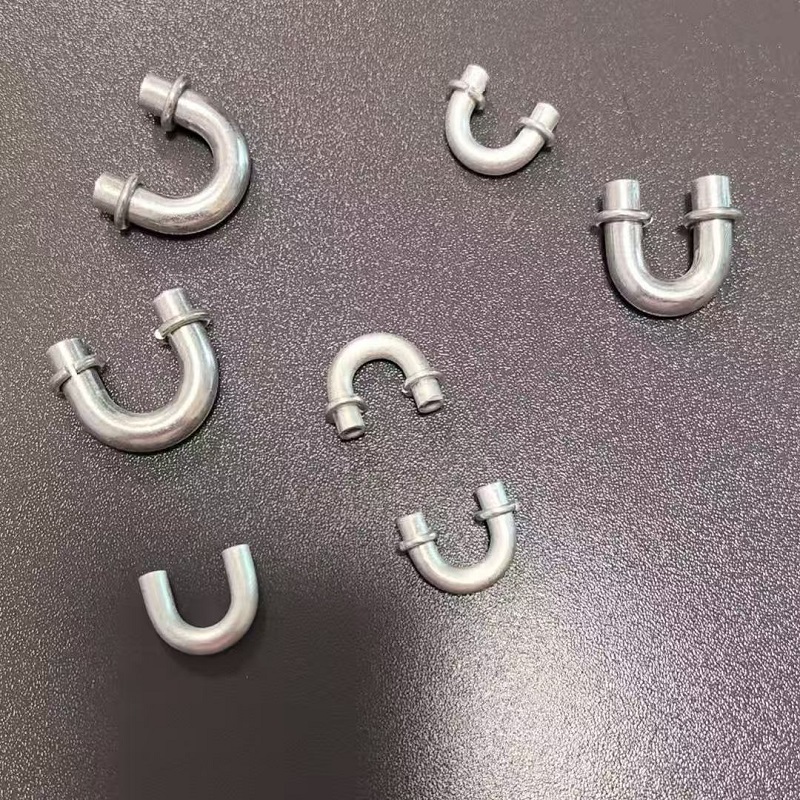

KAK Aluminum Return Bends are engineered for high-efficiency HVAC and refrigeration applications, providing durable and leak-free tubing connections between coils or circuits.

Manufactured from premium 99.7% pure aluminum tubing, these U-type elbows ensure excellent thermal conductivity, corrosion resistance, and long-term reliability under pressure.

Key Features:

• Material: High-purity aluminum (99.7%) with bright, clean finish.

• Structure: Precision-drawn U-bend shape for condenser/evaporator return paths.

• Surface: Smooth interior walls for minimal flow resistance.

• Connection: Easy brazing with aluminum alloy filler or mechanical joining.

• Durability: Rust-proof and anti-oxidation treatment for extended coil lifespan.

• Temperature Range: -40 °C ~ +150 °C.

• Packaging: Sealed bags with anti-scratch and anti-moisture protection.

⸻

Applications

✅ Air Conditioner Evaporator & Condenser Coils

✅ Refrigeration Systems (Commercial & Domestic)

✅ Heat Exchangers & Cooling Units

✅ Refrigerated Display Cabinets

✅ Aluminum Coil-to-Coil Connection or Circuit Return Lines

⸻

Available Sizes (Customizable)

| Tube OD (mm) | Bend Radius (mm) | Leg Length (mm) | Wall Thickness (mm) | Material |

|---|---|---|---|---|

| 5 / 6.35 (1/4”) | 10 ~ 15 | 30 ~ 50 | 0.8 ~ 1.0 | Aluminum 99.7% |

| 7 / 9.52 (3/8”) | 15 ~ 25 | 40 ~ 60 | 0.8 ~ 1.2 | Aluminum 99.7% |

| 12.7 (1/2”) | 20 ~ 30 | 50 ~ 70 | 1.0 ~ 1.5 | Aluminum 99.7% |

| 15.88 (5/8”) | 25 ~ 40 | 60 ~ 80 | 1.2 ~ 1.5 | Aluminum 99.7% |

🛠️ Custom dimensions and OEM/ODM designs available on request.

⚙️ Copper vs Aluminum Return Bends – Comparison for HVAC/R Systems

| Feature | Aluminum Return Bend | Copper Return Bend | Advantage |

|---|---|---|---|

| Material Density | Light (≈2.7 g/cm³) | Heavy (≈8.9 g/cm³) | Aluminum lighter by ~70% |

| Thermal Conductivity | 230 W/m·K | 400 W/m·K | Copper slightly higher |

| Corrosion Resistance | Excellent – natural oxide layer | Moderate – needs coating | Aluminum more durable outdoors |

| Price Trend | ⚡ Lower (≈ 40–60% of copper) | Higher, volatile market | Aluminum cost advantage |

| Processing / Forming | Easier extrusion and bending | Requires more force | Aluminum easier to shape |

| Brazing Method | Needs Al–Si or Zn–Al brazing rods | Cu–P brazing rods | Both reliable with right filler |

| Weight Reduction in System | Major (reduces total coil mass) | Heavy coils | Aluminum ideal for lightweight HVAC |

| Compatibility | Works best with Al tubes | Best with Cu tubes | Match materials to prevent galvanic corrosion |

| Environmental Impact | Fully recyclable, low carbon footprint | Recyclable but high mining energy | Aluminum greener |

| Application Trend | New-generation HVAC, automotive AC, R290/R32 coils | Traditional systems | Aluminum gaining popularity |

🌍 Market Trend

• U.S. & EU: Major HVAC OEMs (Daikin, LG, Gree, etc.) increasingly adopt aluminum coils with aluminum return bends to achieve higher energy efficiency and reduce overall system weight.

• Latin America & Middle East: Copper components remain common in maintenance and retrofit markets due to compatibility with legacy systems.

⸻

📦 Marketing Highlight

💡 KAK aluminum return bends combine light weight, corrosion resistance, and precision forming for modern HVAC and refrigeration coil assemblies. Available in custom diameters and OEM configurations.

FAQ

A: They connect the ends of coil circuits, allowing refrigerant to return smoothly within the condenser or evaporator coil loops.

A: Normally, they are used with aluminum tubing to ensure metallurgical compatibility and prevent galvanic corrosion.

A: Use aluminum brazing rods (e.g., 4047 or Al-Si alloys) under inert gas protection for a strong, leak-free connection.

A: Yes, we support OEM / custom configurations including U-, W-, and S-type return bends for various coil layouts.

A: Each bend is individually bagged, grouped by size, and packed in reinforced cartons or wooden crates with anti-oxidation liners.