Our liquid receivers are designed to stabilize refrigeration and heat-pump systems by storing liquid refrigerant, ensuring liquid-only feed to the expansion device, and providing sufficient pump-down volume during service. The vessels feature a corrosion-resistant powder-coated shell, optional sight glass and service valve, and multiple port layouts to fit vertical or horizontal installations.

⸻

Key Features

• Vertical or horizontal designs; compact footprint with welded feet/brackets

• Optional accessories: sight glass, service valve, safety-relief connection, fusible plug, level indicator/switch

• Powder-coated finish for harsh environments; marine-grade option available

• Compatible refrigerants: HFC/HCFC (HFO/HFO-blends on request; not for transcritical CO₂)

• MAWP 35 bar, burst pressure 190 bar; working temperature –40 to +100 °C

• Clean, dry, and ready for brazing; ODF solder connections

• OEM customization: volume, port size/position, supports, coating, labeling

⸻

Applications

• Condensing units, heat pumps, commercial refrigeration, cold rooms, chillers

⸻

Specifications

• Capacity range (shell volume): 1.1–21 L

• Connection range: 3/8”–7/8” ODF

• Shell diameters: Ø89–Ø219 mm

• Typical models: KAK-101…107 (1.1–14 L), KAK-133…2177 (1–21 L; two top-cover layouts: “a” / “b”)

⸻

How to size(rule-of-thumb)

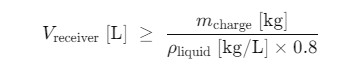

For pump-down and stable liquid feed, select a receiver whose usable volume is at least the total system refrigerant charge at ambient conditions, typically using a fill ratio ≤ 80% to allow thermal expansion.

rule of thumb

Example:

If the system charge is 6 kg and liquid density is 1.10 kg/L, then

V ≥ 6 / (1.10 X 0.8)≈ 6.8 L

→ choose ≥7–8 L.

⸻

FAQ

It stores liquid refrigerant, ensures liquid feed to the expansion device, and provides pump-down volume during maintenance.

Make sure its usable volume can hold the entire system charge at the intended ambient, typically using ≤80% fill ratio. See the sizing note above.

Sight glass, service valve, safety-relief connection, fusible plug, mounting brackets, and optional level indicator/switch.

MAWP 35 bar; burst pressure 190 bar. Not suitable for transcritical CO₂ applications.

Yes—port size/position, supports, labeling, epoxy/marine coatings, and special volumes can be customized.

Rated Products